What we do....

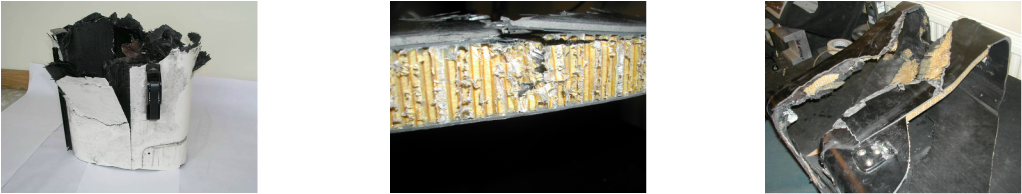

We provide advanced Non Destructive Testing (NDT) inspections on composite materials. Our range of inspection capabilities are broad ranging and we have considerable experience in the inspection of boats, planes and automobiles and parts thereof.

We conduct inspections on new builds, for in service monitoring and also in instances of collision or other damage. We can provide expert witness evidence for insurance claims or litigation. We also work alongside our colleagues within the MTD Group who can provide all manner of technical consultancy. See the link to the main Minton website. All our technicians are trained and qualified to aerospace standards and all our work is fully traceable.

We specialize in:

Laser Shearography

This is a rapid yet sensistive method of NDT that can quickly inspect a structure to determine the extent of any sub surface anomalies such as disbonds or voids. It is very well suited to sandwich laminates. Its use originates from the aerospace industry where the equipment and training required is very costly. We are one of the only inspection services to have this equipment and trained staff in house rather than having to contract this service in. We have both vaccum hood and free standing Laser cameras allowing us a great deal of flexibility during inspections.

Ultrasonics

We use a combination of low and high frequency digital ultrasonics. They are ideal for inspecting monolithic structures such as hulls and masts. We have a vast array of transducers through our work across all industry sectors which allows us the freedom to use the transducer most suited to the structure we are examining.

Bond Testing

This monitors the material’s reaction to an applied vibration. This can detect changes in phase and amplitude to identify issues in the structure under test.

We conduct inspections on new builds, for in service monitoring and also in instances of collision or other damage. We can provide expert witness evidence for insurance claims or litigation. We also work alongside our colleagues within the MTD Group who can provide all manner of technical consultancy. See the link to the main Minton website. All our technicians are trained and qualified to aerospace standards and all our work is fully traceable.

We specialize in:

Laser Shearography

This is a rapid yet sensistive method of NDT that can quickly inspect a structure to determine the extent of any sub surface anomalies such as disbonds or voids. It is very well suited to sandwich laminates. Its use originates from the aerospace industry where the equipment and training required is very costly. We are one of the only inspection services to have this equipment and trained staff in house rather than having to contract this service in. We have both vaccum hood and free standing Laser cameras allowing us a great deal of flexibility during inspections.

Ultrasonics

We use a combination of low and high frequency digital ultrasonics. They are ideal for inspecting monolithic structures such as hulls and masts. We have a vast array of transducers through our work across all industry sectors which allows us the freedom to use the transducer most suited to the structure we are examining.

Bond Testing

This monitors the material’s reaction to an applied vibration. This can detect changes in phase and amplitude to identify issues in the structure under test.

We also investigate composite failures.